Plants since 1961

The production sites extend over a covered area of 20,000 m2 and 45,000 m2 uncovered. The company is located near the PADUA WEST A4 motorway exit.

of history

employees

in the world

Our history

1961

Ravagnan brothers started their first business in mechanical engineering and boiler construction in the Limena industrial park, near Padova, where RAVAGNAN SpA still has its headquarters. Over the years, the production unit grown up to 65,000 m2.

1992

Tecoelettra S.r.l. was founded. This company design and supply electrical/electronic systems and plant automation for industrial and civil sectors. Aside these markets, Tecoelettra allows Ravagnan SpA Plant Division to supply complete turnkey plants all over the world.

1993

Ravagnan de México SA de CV is set up in Monterrey, being a logistics base for production and supplies to the Northern and Southern American markets.

2003

Costruzioni Meccaniche Polesane - C.M.P. SpA is merged into the Group, to serve a wider range of customer needs for bigger equipment expanding Ravagnan commercial possibilities further. C.M.P. is a pressure vessel manufacturer located nearby Rovigo, Italy, close to the Adriatic Sea ports of Porto Marghera and Ravenna.

2014

Ravagnan do Brasil Ltda is established in Belo Horizonte, Brazil. It represents a sales subsidiary of Ravagnan SpA in the Southern America market.

Today

RAVAGNAN GROUP employs 240 people in Italy, and more in Latin America. It’s specialized in design and construction of industrial plant and pressure vessels equipment. The Group has also diversified into aquaculture and agriculture. Annual overall turnover exceeds 50 million Euros. All group companies refer to the parent company RAVAGNAN S.p.A., operating through two integrated divisions, Pressure Vessels Division and Industrial Plant Division.

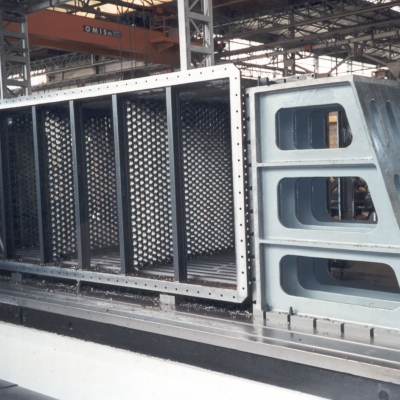

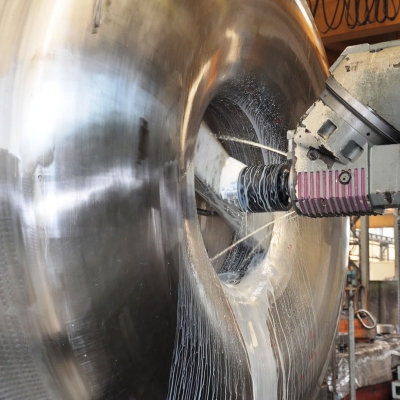

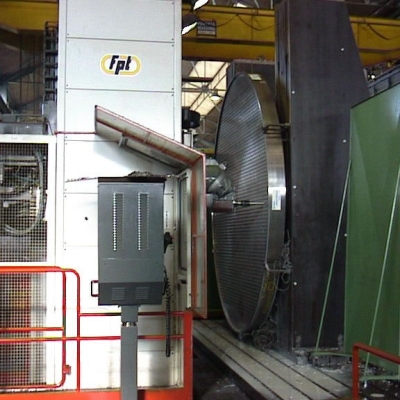

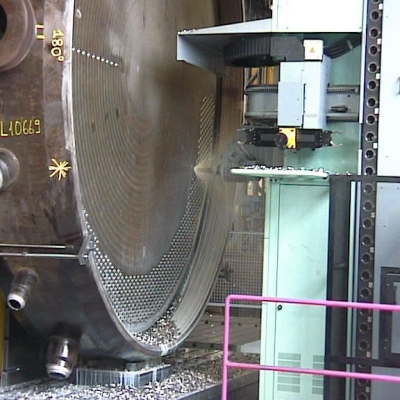

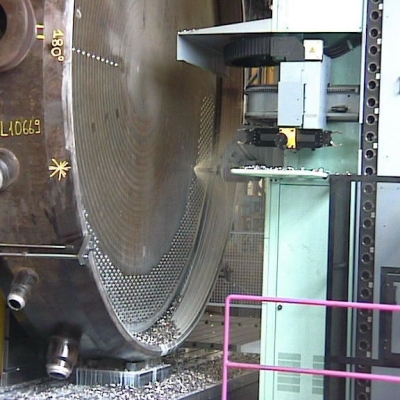

Workshops

Ravagnan’s workshops have a wide range of equipment, including CNC boring mills (carousel and one 5-axis machining), canter lathes, CNC universal milling machines, CNC drilling machines, CNC machining centres with universal head and BTA systems. The Preparation and CNC Department can drill tube sheets up to 6,000 mm diameter and work forgings up to 3,300 mm diameter and 1,800 mm height. Various equipment such as automatic and manual sharpening machines, bevelling, and cutting off machines complete the department facilities.

For emergencies or urgent activities, there are 1,000 ton of certified materials in carbon and stainless steel of different grades and types, in plates from 8 to 130 mm of thickness and exchanger tubes ND ¾” and 1” up to 12 m of length.

For Preparation there are CNC oxygen/high definition plasma cutting machines, oil dynamic press and shearing including rolling capacity up to 70 mm.

In more than 20,000 m2 of sheltered workshops all manufacturing/assembly and repair/maintenance activities are held. Materials normally machined/welded are Carbon and Low alloys steels, Stainless steels, Cladded steels, MONEL® alloys, Copper alloys, Nickel alloys 625, 825, HASTELLOY® alloys, Titanium, etc. The department is equipped with Submerged-Arc plants with weld overlay heads for strip up to 60 mm width, automatic orbital equipment with pulsed GTAW, electric and electronic expanding machines, SMAW for electrodes, wire and cored-wire, positioners up to 140 tons, pits up to 8 m deep for easy re-tubing and horizontal welding of tubes to tubesheet.

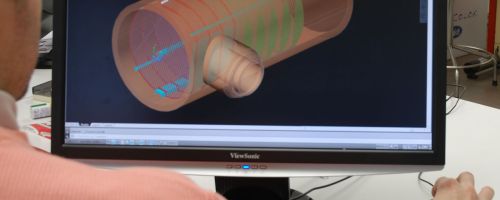

Full digital workflow

Thanks to an entirely digital workflow, from the design and engineering phase made entirely with CAD systems, we move on to the production phase using CAM systems.

Specific programs allow you to size the luminaires according to the main international design and construction standards (PED, EN, ASME, TEMA, AD-Merkblatt, VSR, CODAP, BS, GOST, GB150, CSA B51, STOOMWEZEN, etc.).

a worldwide company

Ravagnan is a global company, present in 3 continents, we can reach most of the planet

Ravagnan S.p.A.

Pressure Vessels Division

Heat Exchangers

Pressure Vessels and Columns

Reactors

Waste Heat Boilers

Plant Division

Plants for the Iron & Steel Industry

Water treatment plants

PVSA Oxygen production plants

Tecoelettra s.r.l.

Plant design and supply

electrical, electronic and automation

Machine and building automation

Photovoltaic and other renewables

Energy Storage

Ravagnan de México

Logistic base for production

and supply to American markets

Address:

Calle "C" No. 513,

Parque Industrial Almacentro

C.P. 66600, Apodaca, Nuevo León

Ravagnan do Brasil Ltda

Sales subsidiary Brazil

Commercial office

for the Brazilian market

Address:

Rua do Ouro 1702 – CEP 30.210-590

Belo Horizonte (MG)

Telefone: +55 31 99264-2974

Ravagnan USA Corp.

US Sales Subsidiary

Commercial office for the US market

Address:

Houston, Tx, USA

Ravagnan per il sociale

In un'ottica di solidarietà e promozione di attività socialmente meritevoli, supportiamo progetti e iniziative come: